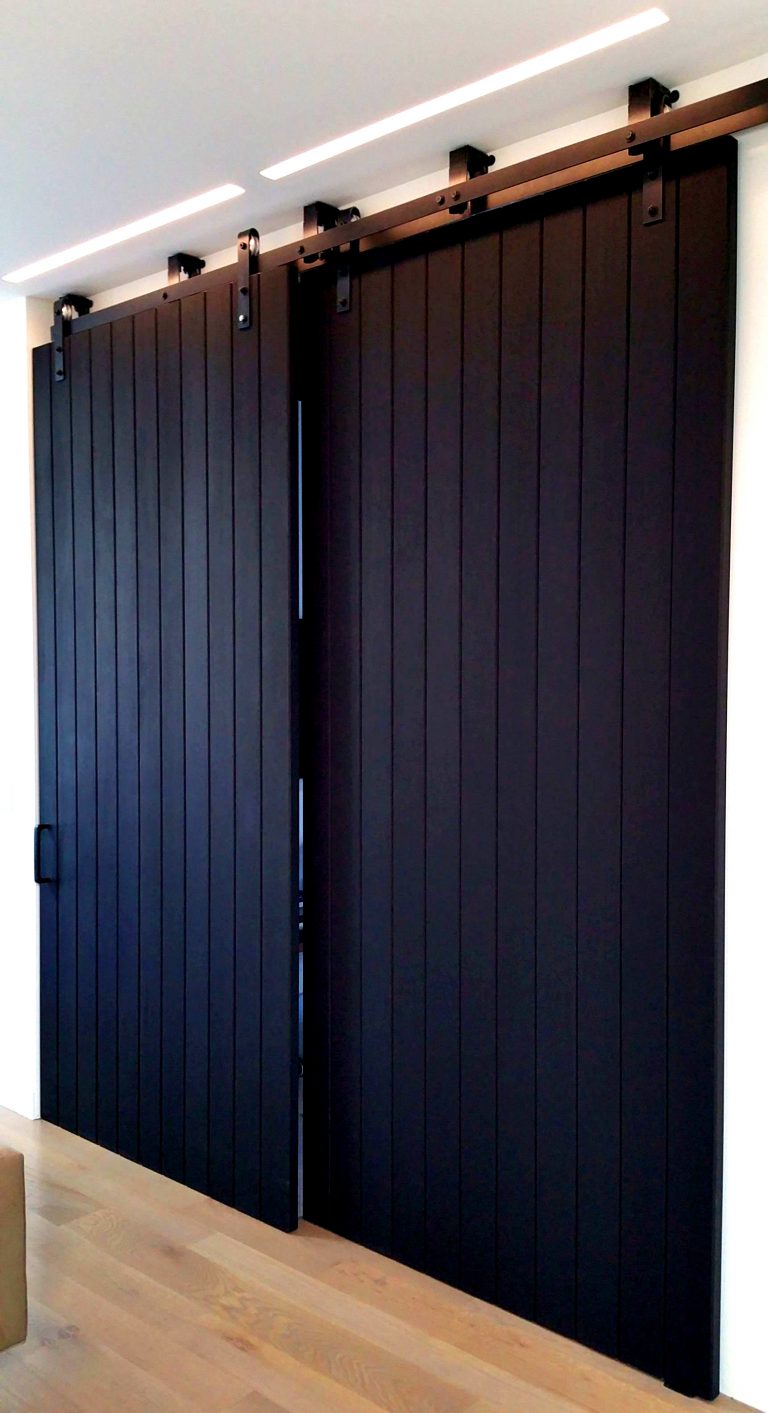

Interior Doors

Interior doors make up a great deal of what we do, here at Modern Doors for Sale, because we specialize in the best modern doors with the characteristics which are in the highest demand in the most high-end contemporary architecture designs in the world today.

These unique solid modern interior doors are Eco-friendly insulated lightweight, high strength interior doors that are solid as a rock and are the only doors in this category that can be guaranteed not to warp, bend twist or otherwise fail for 50 years.

Our most popular interior doors are solid wood doors with patented Sing Core inside and as you may already know are oak doors, mahogany doors, knotty alder doors, walnut doors, white oak doors and douglas fir doors, as well as smooth birch-skinned door blanks for white primed doors.

Thanks to our patented reinforced vertical grain torsion box core, we can make doors of any size that not only will not warp, but they also provide better separation between adjoining spaces, with increased climate control and sound deadening qualities unavailable in any other high-strength lightweight door.

And when we say available in any size, we mean it. Your large modern doors for sale can be any size (up to 50 ft.) and still be guaranteed for 50 years.

How strong, you might ask, are our modern doors for sale? Stronger than steel pound-for-pound as they were independently tested at more than 660 PSI.

Front Doors

Where modern doors for sale shine with their brightest sheen is when they are specified as front doors for many of the same reasons they are celebrated as interior doors, but as exterior doors these modern doors with patented composite torsion box core are by far the best front doors made in the USA.

Front doors are the most potentially problematic due to having one side of the door facing the weather (if it is an entry door facing outside) while the other side faces the structure’s interior space, which is routinely a different climate altogether. Often exposure to heat, sunlight, or moisture can cause the door to warp, bend, twist, or cup.

That’s where the True Straight Door Team at modern doors for sale comes in. We are able to design professional wooden front doors that can be used as entrance doors, and are the only exterior wood doors that can be guaranteed to remain warp-free for 50 years, including full structure warranty.

These specially-designed modern front doors are having a huge impact among the door industry. If you desire to have our warp-free exterior doors as the gateway to your home, or as commercial doors, all you have to do is to go wherever you find front doors for sale and tell them you want the only front door that has a 50-year guarantee.

We make a lot of wooden doors because of the problems associated with the nature of working with the combination of natural wood grains and our insulation vertical grain torsion box core solid composite core, as well as out patent pending true straight door reinforcement for natural woods that have an increased tendency to move. We also are well-known for making modern exterior doors of other materials, too. The most highly requested are our,

Steel Doors

Eco-friendly metal doors made by Modern Doors for Sale far outperform any other metal doors in terms of lightweight, high strength and more high precision than any other metal doors. Our patented manufacturing method enables us to make a metal door using less energy with no toxic fumes or waste, unlike traditional metal working, plus we use high-precision core with .006 in tolerances. No other Eco-friendly lightweight high strength door can be made so precisely.

Steel doors are at the top of the list for our high precision metal doors. No matter what size or type of steel doors your looking for to use as either residential steel doors or commercial steel doors, Modern Doors for Sale has the steel doors you’ve always wanted to have.

Having steel doors that weigh-in at a fraction of the weight of other steel doors with the advantage of not compromising strength because our modern steel doors are rated at more than 660 PSI (stronger than steel pound for pound), puts the end use far ahead of the pack in terms of safety, security and longevity with must less costs incurred from installation to maintenance over time.

Many type of steel doors are available including (but not limited to) hot rolled steel doors, cold rolled steel doors, stainless steel doors, diamond plate steel doors, and galvanized steel doors. While cold rolled steel doors are by far the most popular, rising in popularity are hot rolled steel doors which give you that one-of-a-kind industrial look at feel which is unmistakable and demands attention from anyone who enters a room where they are featured.

If you’re incorporating steel doors in your contemporary architectural door specifications, a modern steel door with the characteristics of modern doors for sale, might be the best decision for your high-end project.

You can find our modern doors for sale wherever you find modern doors for sale.