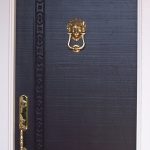

Amidst the landscape of the door industry modern front doors are emerging in the marketplace as more highly sought after than traditional front door designs. When designing, specifying, building and installing modern front doors, they can appear to look like any traditionally designed door, but they are very different indeed.

What makes our modern front doors so different?

Basically, unlike traditional doors, modern front doors are lightweight, high strength, and impervious to varying weather conditions.

If you look at the basic characteristics of a traditional door, you see a basic method of blocking an egress point opening with a slab of wood (or other purportedly flat building material) which articulates with hinges or sliders to allow and prevent access to a particular area. While a plain flat slab door may be very basic, modifications and enhancements can be added to the slab to increase the door’s superfluity, such as adding moulding or trim, cutting lite openings and inserting glass, or various and sundry finishing techniques to provide a certain aesthetic appeal.

Modern front doors armed with our patented warp-free solid door core inside are at least one-third the weight of their counterparts and many times stronger. Our patented door core has been independently laboratory rated at 620+ PSI, and stronger than steel pound for pound.

This enables the end user to possess a modern front door that is both lightweight and high strength which can be guaranteed not to warp, bend, twist, or otherwise fail (including full structural warranty) for 50 years. A 50-year warp-free guarantee is unheard of in the industry unless it has our patented warp-free door solution inside.

This translates into incredible flexibility when designing, specifying, and manufacturing high end modern door solutions for residential, commercial, and industrial door applications because now you can build doors of any size of any available flat building materials that can be guaranteed for 50-years.

It doesn’t matter whether you’re considering a modern front door for a house, which could be a 10-foot-tall pivot door, or a pair of 20 x 20 ft. double doors for your factory, or a 40-ft. tall industrial front door, or even a pair of hangar doors to protect your aircraft, they all can be made of any material, have the highest precision and performance over time, reducing overhead and maintenance exponentially, and all of them can be backed by the same 50-year warp-free guarantee.

The most popular surface material for our warp-free modern front doors is any species of available natural wood grain because it is the most problematic building material in terms of warp with a relatively low R-value (R1) per inch, while building the same door with our patented modern front door core inside results in an R value of R6.5. This is excellent for both increased climate control and sound deadening qualities, while retaining all the beauty and elegance of natural wood grains.

Other materials used to manufacture modern front doors include aluminum, brass or bronze, concrete, fiberglass/FRP, glass, HPL, Kevlar, LVL, MDF, and a variety of modern steel front doors including cold rolled steel, diamond plate steel, galvanized steel, hot rolled steel, and stainless-steel front doors, which can all be lightweight and guaranteed not to warp or fail for 50 years.

How can I get warp-free modern front doors?

No problem, simply visit any local manufacturer featuring modern front doors for sale, or your local millwork specializing in custom built modern front doors. Tell them to contact us if they don’t know about us yet, and we’ll work out all the details with them.

You could be the proud own of the best modern front doors available backed with a full 50-year guarantee.

We provide out warp-free solutions to the best door companies and millworks. Need to find a millwork? Google: millworks near me